PE Juice Bottles Manufacturers

About

Our company offers a variety of products which can meet your multifarious demands. Since its establishment, we adhere to the management principles of "Stable quality, continuous and reliable product supply, and credit-based" and always do our best to satisfy potential needs of our customers.

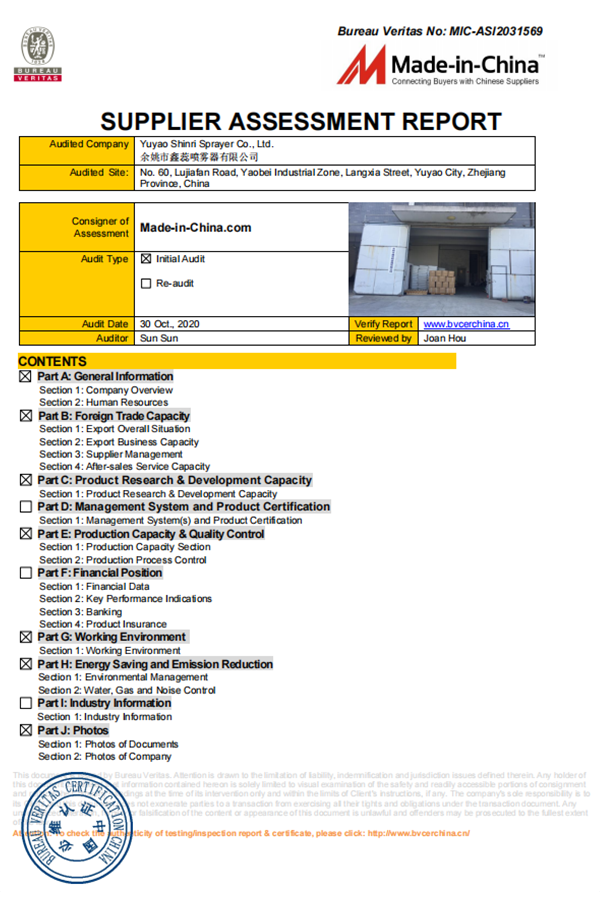

Yuyao Shinri Sprayer Co., Ltd. is leading China ODM PE Juice Bottles manufacturers, has 16000 square meters of scale, including 10000 square meters of Nozzle Factory (YSR: Yuyao Shinri Sprayer Co. Ltd), 6000 square meters of bottle factory (YS: Zhejiang YiSi Commodities Co., Ltd),with annual output over 100 million pieces of all kinds of products. As a famous wholesale PE Juice Bottles factory, we devote our efforts to research and develop safe, fashion, environmental and economy products. Creating value for customers is our aim. At present, products are mainly involved in personal care, cleaning, perfume packaging, medical packaging, cosmetics packaging, wholesale PE Juice Bottles, and other fields, and we are in cooperation with some famous enterprises in the relevant industry.The company also provides customized service, providing customers with "charm" personalized packaging. Relying on advanced professional technology, excellent management personnel, we provide more efficient and high quality service for the customer. The company also provides customized service, providing customers with charming personalized packaging. Relying on advanced professional technology, excellent management personnel, we provide more efficient and high quality service for the customer. At present, the company has a complete set of technology and equipment, such as advanced mold designing, steel mold manufacturing, fully automatic injection molding, and fully automatic assembly and inspection, hot stamping services, etc. The company controls the quality strictly, and has complete testing equipment. "Insist on stable quality, continuous and reliable product supply," is the core of our enterprise culture, and the company all staff with enthusiasm to create high quality products for customers, and to continue to provide competitive products. The company focuses on independent research and development, Track innovative technologies, exploring the feasibility of new materials, new technology applications, through cooperation with relevant domestic institutions. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.

Professional

We have a strong R&D team, and we can develop and produce products according to the drawings or samples the customers offered.

Quality & Cost

We have two own casting foundries and one CNC machining factory, so we can offer the high quality products with reasonable price directly.

Make High Quality, Low Price and Fast Delivery Possible

We have our own factory to produce and sell directly, so the price is cheap.

-

Are There Different Types of Nozzles Available for Trigger Sprayers?

When it comes to trigger sprayers, the variety of nozzle options available plays a crucial role in their versatility an...

-

What are the features and applicable scenarios of Crimp Perfume Liquid Dispenser Mini Sprayer?

As a new type of perfume sprayer design, Crimp Perfume Liquid Dispenser Mini Sprayer has attracted much attention for it...

-

How to clean the inside of a cream jar?

Cleaning the interior of the cream jar requires a few attention and persistence, especially while residues of cream or d...

-

What should I do if the items inside cannot come out when cleaning the cream jar?

If the residue inside the cream jar is tough to dispose of, the following techniques may be tried to thoroughly clean:1....

-

Are cream jars recyclable?

Cream jars are recyclable. Recyclable substances check with garbage that may be recycled and recycled, which includes pa...

-

Are cream jars suitable for traveling?

Cream jars are usually suitable for travel, especially small, lightweight, and compact design cream jars. Here are some ...

PE (polyethylene) juice bottles are containers typically used for packaging and storing various types of juices. Polyethylene is a widely used plastic material known for its durability, flexibility, and resistance to moisture and chemicals. Here are some key points about PE juice bottles:

1.Material: PE juice bottles are made from polyethylene, a thermoplastic polymer derived from petroleum. It is a lightweight and translucent material.

2.Types of polyethylene: There are different types of polyethylene, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE). HDPE is commonly used for juice bottles due to its strength and rigidity.

3.Properties: PE juice bottles offer several advantageous properties, such as being shatter-resistant, leak-proof, and having good impact resistance. They also provide a barrier against oxygen and moisture, helping to preserve the freshness and flavor of the juice.

4.Recyclability: Polyethylene is a recyclable plastic, and many PE juice bottles are designed to be recycled. Proper disposal and recycling of these bottles can help reduce environmental impact.

5.Sizes and shapes: PE juice bottles come in various sizes and shapes, ranging from small individual-serving bottles to larger containers for bulk packaging. They can be cylindrical, rectangular, or have custom designs depending on the brand and product.

6.Closure options: PE juice bottles typically have screw caps or flip-top lids for easy opening and resealing. These closures help maintain the integrity and prevent spillage of the juice.

7.Safety considerations: When using PE juice bottles, it's important to ensure they are free from any chemical contaminants and comply with food-grade standards to ensure the safety of the product.

8.Labeling and branding: PE juice bottles offer a smooth surface that is suitable for labeling and branding purposes. Companies often print nutritional information, branding elements, and other relevant details on the bottle.

To recycle PE (Polyethylene) juice bottles, you can follow these steps:

1.Empty and Rinse: Empty the juice bottle completely, making sure there is no leftover juice inside. Rinse the bottle with water to remove any residue.

2.Check for Local Recycling Guidelines: Look up your local recycling guidelines to determine if PE juice bottles are accepted for recycling in your area. Recycling programs may vary depending on your location, so it's important to know what is accepted.

3.Remove Caps and Labels: If your local recycling guidelines allow, remove the caps and labels from the bottles. Some recycling facilities prefer separate recycling streams for caps, labels, and bottles.

4.Flatten the Bottles: Flatten the juice bottles to save space in your recycling bin. You can do this by gently pressing or stepping on them, ensuring they are completely empty and dry.

5.Sort and Separate: If your recycling program requires sorting, separate the PE bottles from other types of plastic or recyclables. This will help streamline the recycling process and ensure the bottles are recycled properly.

6.Place in Recycling Bin: Put the flattened PE juice bottles in your recycling bin or take them to a designated recycling drop-off point in your community. Follow the specific guidelines provided by your local recycling program to ensure proper disposal.

7.Check for Special Programs: Some areas have special recycling programs for specific types of plastics, including PE. Check if there are any special recycling programs or collection events dedicated to PE bottles in your area.

English

English Español

Español